|

|

1.

Description of Flying Vehicles "EKIP"

In

the Closed-Stock Company "Aviation Concern "EKIP" the

specialists of aviation and space-rocket branches of industry guided

by professor L. N. Schukin developed the fundamentals of principally

new type of flying vehicles "EKIP".

The "EKIP" aircrafts can carry heavy large-scale loads (100

and more tons) at long distances (thousands of kilometers) at a speed

of 500-700 km/h at the altitude of 8-13 km. These flying vehicles

can move near the surface of ground or water using the air cushion

at a speed up to 160 km/h and glide at a speed up to 400 km/h as a

"screen-plane".

The flying vehicles "EKIP" do not require an airfield. They

can land on airfields of any category, including ground and water

surfaces. The length of the runway for heavy vehicles (several hundred

tons) does not exceed 600 meters, take-off and landing are performed

at steep descent trajectory, which decreases the level of noise affecting

the vicinity.

An air cushion device is used for takeoff and landing of flying vehicles

"EKIP". The profound air cushion research developments made

at the State Scientific Research Center TSAGI (Moscow Branch of Central

Air-hydrodynamic Institute), could not be used in traditional existing

airplanes due to absence of large planer area.

The flying vehicles "EKIP" have large planer area and the

air cushion landing gear ideally fits with the structure of the aircraft.

It is located under the body of the vehicle and ensures that low pressure

is exerted on the vehicle itself and on the runway (ground, water

surface) during takeoff and landing.

This pressure is equivalent to the pressure of a layer of water 220-270

mm thick.

For the flying vehicles "EKIP" with a load-carrying capacity

of hundred tons there is no necessity to build special airfields with

concrete runways 5 km long, as it is necessary for heavy airplanes

like B-777 (Boeing) and A3-XX (Airbus Industry). |

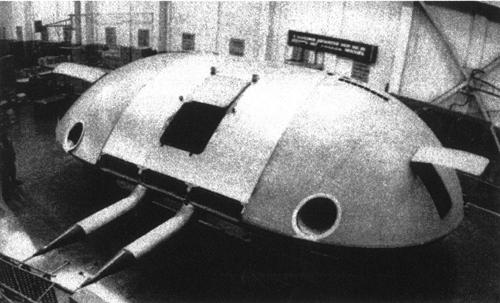

Mock-up

of Passenger Variant of Flying Vehicle

Mock-up

of Passenger Variant of Flying Vehicle

|

The

flying vehicles "EKIP" will transport heavy loads and large

numbers of passengers (1000 and more) to the existing airfields of continental

and waterlocked countries.

It should be specially noted that the flying vehicles "EKIP"

may use gas fuel (natural gas and hydrogen). Large volumes of the flying

vehicle permit to locate inside it without changing the external contour

large volume gas fuel tanks. Limited resources of oil (to last for 50

years) require transition of airplanes to gas fuel. However limited areas

of thin wings of existing airplanes do not allow this transition. As the

gas fuel occupies half of passenger compartment on airplane Tu-156 and

in airplane A-310 (DASA project) the fuel occupies the whole area above

the passenger compartment thus changing the external contour of the airplane

and decreasing its lift-drag performances. The flying vehicles "EKIP"

permit due to large volumes to locate the fuel tanks in the lateral part

of the aircraft without changing the external contour of the vehicle.

It

should be noted that with the use of hydrogen fuel the flying vehicles

"EKIP" may increase the range of flight 2-3 times compared to

existing airplanes of the same load-carrying capacity. Operation of flying

vehicles "EKIP" using natural gas and hydrogen will permit to

decrease contaminating emissions of exhaust products, i.e. the flying

vehicles "EKIP" will be more environmentally safe than the existing

airplanes.

It should be specially noted that use on the flying vehicles "EKIP"

of liquid methane will allow to reduce the fuel expenses more than 5-8

times, which should result in a decrease of operating expenses 1.5-2 times

compared with the existing airplanes.

We should pay special attention to the design of the body of flying vehicles

"EKIP". The relative weight of the structure of the vehicles

body (compared to takeoff weight) is 30 % lower than the weight of existing

airplanes due to the use of composite materials according to the estimation

of the DASA special ists. This difference in the weight of the structure

re-

Assembly

of Flying Vehicles "Ekip" at Saratov Aviation Plant

suits

in the increase of commercial load by 30 % at fixed range of flight. The

possibility to use composite materials in the body of flying vehicles

"EKIP" is related to the absence of concentrated loads on the

body as a result of absence of large wings and traditional wheel landing

gear. Under all flight conditions, including takeoff and landing, the

body of the aircraft is under uniformly distributed load, the static component

whereof does not exceed the load of a layer of water 300 mm thick. The

tail unit of flying vehicles "EKIP" is used for location of

aerodynamic control surfaces.

The power unit of flying vehicles "EKIP" is located inside the

body, in the stern part. It consists of two or more thrust high economy

by-pass turbojet engines and two or more auxiliary high-economy dual generator

turboshaft engines. The power units provide for motion of the vehicle,

whereas auxiliary engines provide for operation of air cushion landing

gear and boundary layer control device ensuring steady airflow around

the body of flying vehicles

"EKIP" and decrease

of drag. During takeoff and landing the auxiliary power units operate

in the maximum power mode, whereas during the cruising flight they operate

in maximum economy mode.

The location of thrust bypass engines inside the body of the aircraft

permit to create afterburners for the by-pass ducts providing substantial

increase of thrust under takeoff condition.

The location of thrust bypass engines inside the body of the aircraft

permit to create afterburners for the by-pass ducts providing substantial

increase of thrust under takeoff condition.

The power units and the auxiliary engines operate under all flight conditions,

the flying vehicles "EKIP" have no unnecessary complicated elements

like the wheel landing gear, the failure whereof is currently the cause

of 70 % of accidents. The deviation of flat nozzles ensures pitch control.

The gas power jets of flat nozzles are more quickly damped in the environment,

which results in decreased noise in the regions surrounding the runways.

"Ekip"

Flying over the Saratov Airfield

The

power units and the auxiliary engines operate under all flight conditions,

the flying vehicles "EKIP" have no unnecessary complicated elements

like the wheel landing gear, the failure whereof is currently the cause

of 70 % of accidents. The deviation of flat nozzles ensures pitch control.

The gas power jets of flat nozzles are more quickly damped in the environment,

which results in decreased noise in the regions surrounding the runways.

To ensure directional and roll control at low speeds of flight pulse control

engines are mounted on wing tips, using the main fuel (and natural gas)

and compressed air taken from main power units.

The flying vehicles "EKIP" ensure elevated level of flight safety.

When (all) power units are de-energized the flying vehicle may perform

a safe landing on the ground or water surfaces. In order that the auxiliary

engines become disconnected it is necessary that all (minimum four) gas

generators fail. This is hardly probable. In case even one gas generator

is in operation

it should be transferred to the

maximum power mode, thus the steady airflow around the body of the vehicle

is ensured and the landing is safe even in case ,of failure of power units.

The basic design feature of flying vehicles "EKIP" is the new

vortex control system (UPS) of the airflow in the boundary layer mounted

on the stern surface of the aircraft. This system ensures steady airflow

around the body of the vehicles and decreases its drag by creating a set

of aggregate of consecutive cross vortex. The vortex boundary layer airflow

control system is patented in Russia and abroad in Europe, USA and Canada.

It allows at low level of power consumption (6-8 % of the thrust of power

engines) to ensure steady airflow around the vehicle body during the cruising

flight and during takeoff and landing at angle of attack up to 40°.

With the use of the vortex boundary layer airflow control system and the

control engines the flying vehicles "EKIP" may perform a "bird

landing" at high glide slope at landing speed decreased down to 100

km/h.

Tests

of Flying Vehicles "Ekip" at Saratov Aviation Plant

|